Low-E coated glass

Low Emissivity (Low-E) glass is an invisible metallic coating applied to the glass surface to enhance its insulating properties, naturally regulating building temperatures. They are applied at the time of manufacture and are not an after market film.

Among them are essentially three coating categories – Magnetron Sputtered Coatings, Pyrolytic Coatings and now Indium Tin Oxide Coatings. Learn about how they work and how to specify/glaze them.

Low-E Magnetron Sputtered Coatings

This is the main type of low-E coating (also known as a Soft Coat or Sputtered Coat). They incorporate an invisible layer of silver which makes them better performers for solar control, however the coating cannot be exposed and therefore must be glazed inside a double glazed unit for the best results,

Glassworks Low-E Magnetron Sputtered Coated products include:

- LoE³-366® – a neutral colour mixed climate triple silver low-E

- LoE³-340® – a bluish colour solar control triple silver low-E

- Optitherm® – an ultra clear cool climate single silver low-E

Low-E Pyrolytic Coatings

Then there are Low-E Pyrolytic Coatings (also known as Hard Coat or Room Side Coat) which are tough enough to be exposed and can therefore be coated on the room side surface of a single or double glazed unit, performing better when double glazed.

They are the perfect entry level low-E coating type in terms of price and appearance and whilst being the most versatile, don’t offer quite the same solar performance as Magnetron Sputtered Coatings.

Some Low-E Pyrolytic options are included in the Glassworks EnerSave® range incorporating coatings such as Soltech and EnergyTech.

Low-E Indium Tin Oxide Coatings

Like Low-E Pyrolytic Coatings, another low-E coating tough enough to be exposed room side is Indium Tin Oxide Coating (ITO). Better still, as it is technically a Magnetron Sputtered Coating – only not silver based – it does not necessarily have to be double glazed and is smoother and clearer in appearance than Pyrolytic Coatings.

Glassworks’ LoE-i89® is the only ITO coating on the Australian market.

Glazing tips

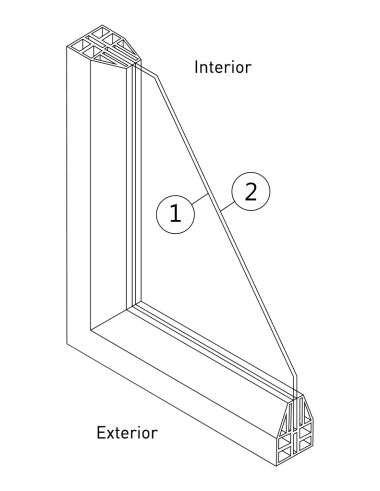

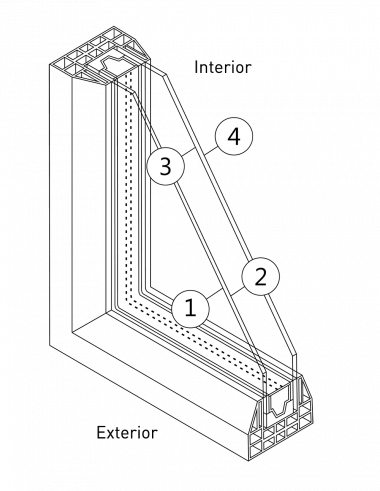

- Low-E Magnetron Sputtered coatings are nearly always applied to surface 2 as they give a better appearance and perform better in warm climates – absorbing the solar radiation and reflecting it back outside. However they may be applied to surface 3 for colder climates to absorb the heat and re-radiate it back inside.

- Low-E Pyrolytic coatings are applied to surface 2 in a single glazed unit and surface 4 in a double glazed IGU. Of course these perform far better as glazed IGUs.

- Low-E Indium Tin Oxide coatings may also be applied to surface 2 when single glazed or surface 4 when double glazed. They also perform better as a double glazed units. However best of all, in an IGU they can be applied to surface 4 and couple with a Magnetron Sputtered coatings on surface 2, achieving unprecedented U-Values

Double glazed / Insulated Glass Unit

Single glazed / monolithic unit